2023-01-24

2023-01-24

loading...

loading...

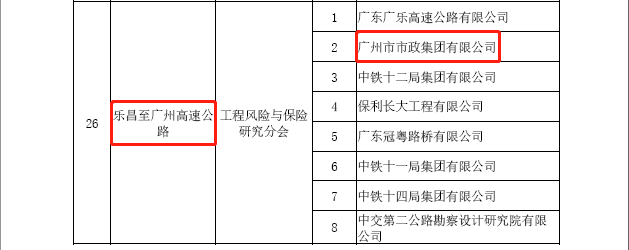

Recently, GMC carried out an on-site tour to observe the construction technology of Drilling with PHC Pipe Cased Pile (DPC) piles at the Construction Research Innovation Building project site in Baiyun District of Guangzhou, aiming to promote the exchange and learning of the construction technology of DPC piles and advance the innovative development of green and environmental-friendly construction technology. The observation tour was organized by GMC Chief Engineer Office, undertaken by GMC's subsidiary Guangzhou Institute of Building Science Group and Guangzhou Hengsheng Construction Engineering Co., Ltd, and attended by chief engineers and technical department heads of GMC's subordinate enterprises.

During the event, Mr. Shao Quan, Deputy Chief Engineer and Director of the Chief Engineer Office of GMC, and Dr. Ling Zao introduced the development process of the construction technology of DPC piles, expressing an expectation that all subordinate enterprises would further strengthen the exchange and cooperation on the technology, to jointly boost the wider application of the construction innovative technology self-developed by GMC.

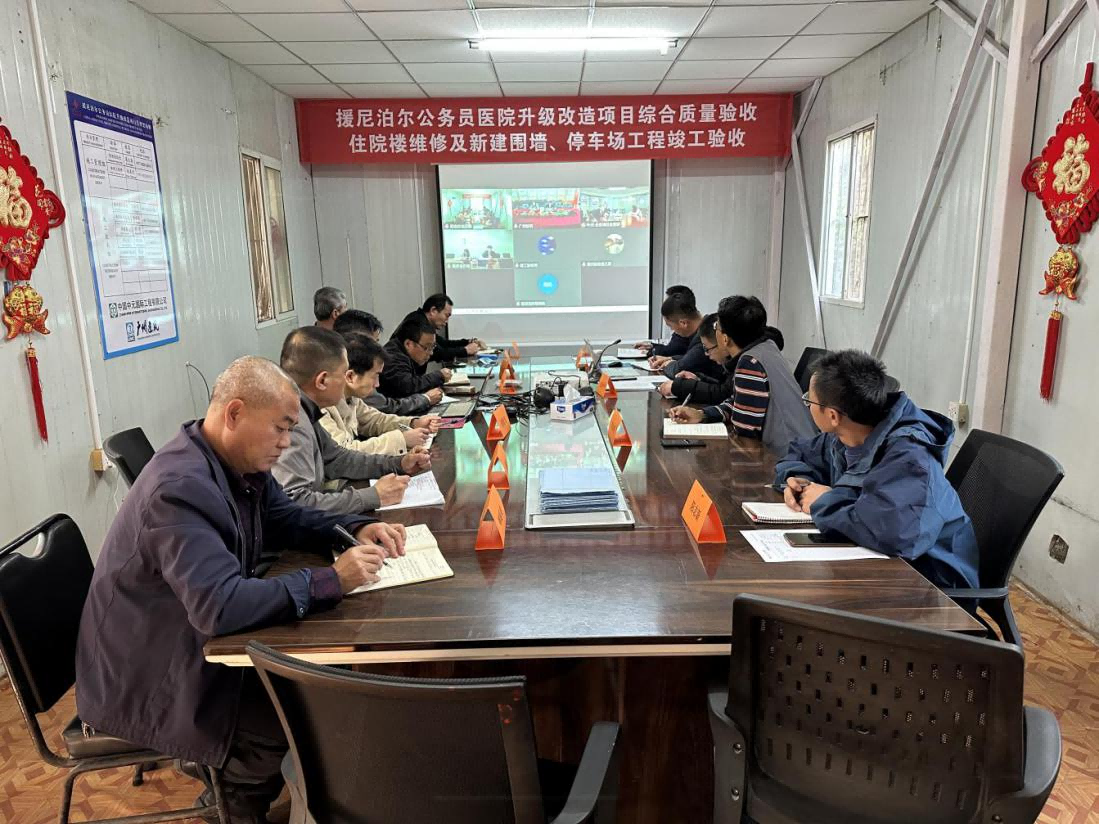

Dr. Su Dingli from the Guangzhou Institute of Building Science Group also briefed on the application of the DPC pile construction technology in the Construction Research Innovation Building project. The project adopts large one-meter-diameter pipe piles for the foundation pit support, with a maximum depth of about 16 meters to the pile bottom. The soil layers that the piles penetrate through are mainly artificial fill, silty clay, completely weathered rocks, highly weathered rocks, and moderately and slightly weathered argillaceous siltstone. Since the commencement in December 2022, the foundation pit support work of the project has progressed smoothly, and the piles have been successfully fed to the required elevation according to the design requirements. The construction speed is fast, without soil squeezing, slurry discharge, and vibration noise pollution, fully reflecting the green and environment-friendly features of the DPC pile construction technology.

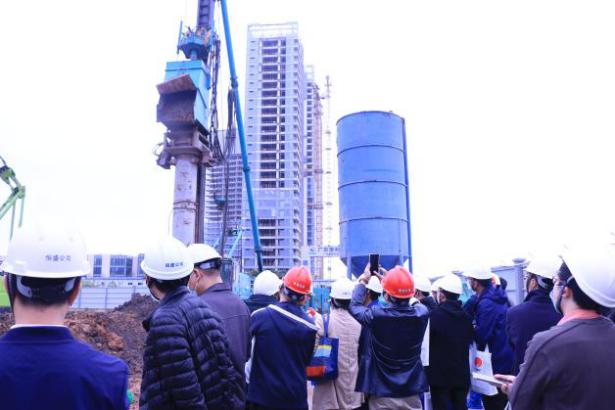

▲Participants engaging in observation and technical exchanges

Soon afterwards, with the explanation of the project team, the participants observed the construction process of DPC piles and conducted exchanges on the technology.

Relevant links:

The 'Fourteenth Five-Year' Development Plan for the Construction Industry issued by the Ministry of Housing and Urban-Rural Development in 2022 proposed that the focus of the industry should fall on developing prefabricated buildings and promoting green, industrialized and intensive construction methods. Compared with the above-ground buildings and bridges, it's much more difficult to apply the fast-speed and green prefabricated construction mode for underground pile foundation works due to the complex and changeable geological environment.

After more than ten years of research and study, the Guangzhou Institute of Building Science Group under GMC has successfully broken through the limitation of traditional pile foundation construction methods and developed the construction technology and complete equipment of DPC piles. Combining the strength of both the cast-in-place pile and precast pile, this technology adopts the drilling-in method for construction. Before drilling on the ground, the long auger drill pipe is inserted into the inner cavity of the precast pile, whose outer diameter is slightly smaller than the retractable drill bit at the bottom of the drill pipe. During drilling, the pipe and pile sink down simultaneously, and the by-product of muck is delivered from the bottom up to the ground through the auger drill pipe blade. After reaching the required elevation for pile sinking, the drill pipe rotates reversely up to the ground and the drill bit is withdrawn from the inner cavity of the pile, followed by muck removal, bottom sealing concrete pouring, and pile end and pile side grouting before the construction is finally completed.

The construction technology of DPC piles synchronizes the three operations of drilling, pile sinking and dumping, which is highly mechanized and green, protecting the pile body from quality defects and avoiding environmental pollution such as noise, vibration, and slurry discharge. Meanwhile, it fundamentally solves the technical problems of large-diameter pipe pile sinking and rock penetration, greatly broadens the application scope of engineering geology of pipe piles, and initiates the process of industrial production, mechanization and integrated construction of large-diameter pipe piles.

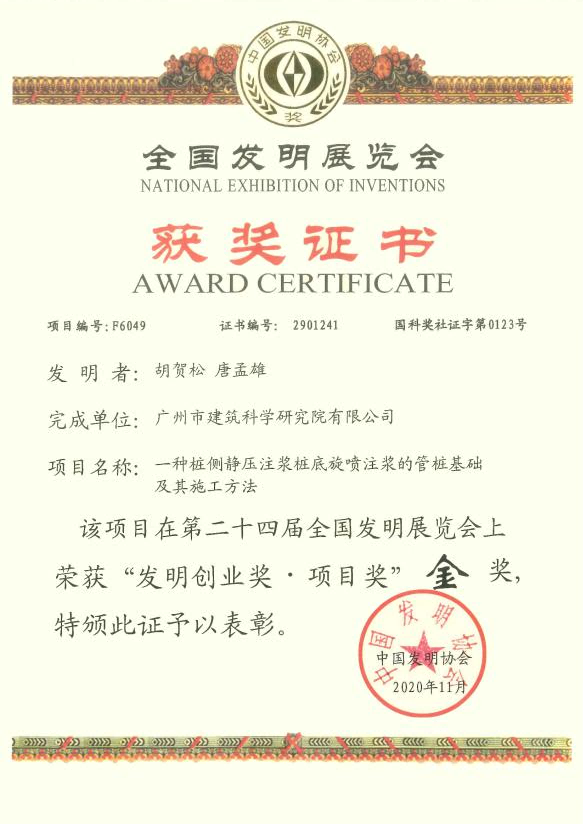

Technology Achievements: 25 national invention patents and 1 US invention patent; winner of the Silver Award of the Concours Lepine International Paris and the Gold Award of the National Exhibition of Inventions; products certified as high-tech products in Guangdong Province; 1 industry standard manual as editor-in-chief. Besides, the construction technology of DPC piles has been successfully applied in many projects such as the Shanty Town Renovation Project of Shatinggang New Community in Baiyun District of Guangzhou, the Tangkou Plot Renovation Project in Huangpu District of Guangzhou, as well as a housing construction project in Zhuhai.

Source: Ling Zao, GMC Chief Engineer Office; Su Dingli, Guangzhou Institute of Building Science Group

Edited and released by Lu Chongyou and Long Kun, Party-Masses Work Department of the Group

Released by Zhang Xiaoying, Group Office